Recovering Today and Preparing For Tomorrow – Top 4 Things To Do For Your Supply Chain and Operational Readiness

There is no need to explain the impact of the current COVID-19 crisis on the lives of individuals, families, communities and companies around the world. It is, in many ways, unprecedented, and certainly represents a once-in-a-generation challenge to us all.

The outbreak has caught companies and some entire industries by surprise with sudden dramatic drops in demand, changes in customer behavior and general uncertainty. Normal demand signals have disappeared, and the effect has rippled through the whole supply chain. While remote work is possible for many, critical manufacturing and service jobs can’t be done “from home”, and even if they could, how would you know what to produce, or order and for how long?

As we all look to follow the public health guidelines to protect our families, friends and colleagues, business leaders can and must look to not only recover from this crisis, but to be ready for the next one. We cannot predict the future, but we can learn from every experience and put ourselves in a better position next time. Doing that is the hallmark of a “learning organization”, and the essence of proactive leadership. So, how can businesses position their supply chains to be more flexible and resilient – more ready, if you will?

There are several concrete actions businesses can take right now to prepare even as they recover:

1. Conduct a thorough assessment of all aspects of the supply chain – sunlight is the best disinfectant

If recent events have taught us anything, it’s that speed + flexibility = resiliency. In planning your assessment, consider all aspects of the supply chain. If there are obvious weak spots look there first. But be prepared to look everywhere.

- Use current disruptions to guide you – are your gaps in procurement, supply/supplier certainty, transportation, inventory planning, production capacity or logistics?

- Decide what success looks like – what are the essential elements of a short, mid and long-term strategy to navigate current challenges while being better situated for disruptions? Engage with partners and suppliers to get the best ideas and plan with them to promote everyone’s shared interests.

- Develop an actionable plan – the assessment is useless unless it leads to a plan. Put the plan on paper, engage the right resources to execute the plan. Make sure the plan is rigorous enough to make a difference and flexible enough to be practical.

2. Diversify the supplier network to de-risk your supply chain

Define critical-to-value and critical-to-mission factors for serving customers and managing operations, and source accordingly. Ask the hard questions about risk and total cost, and engage the marketplace to build resiliency.

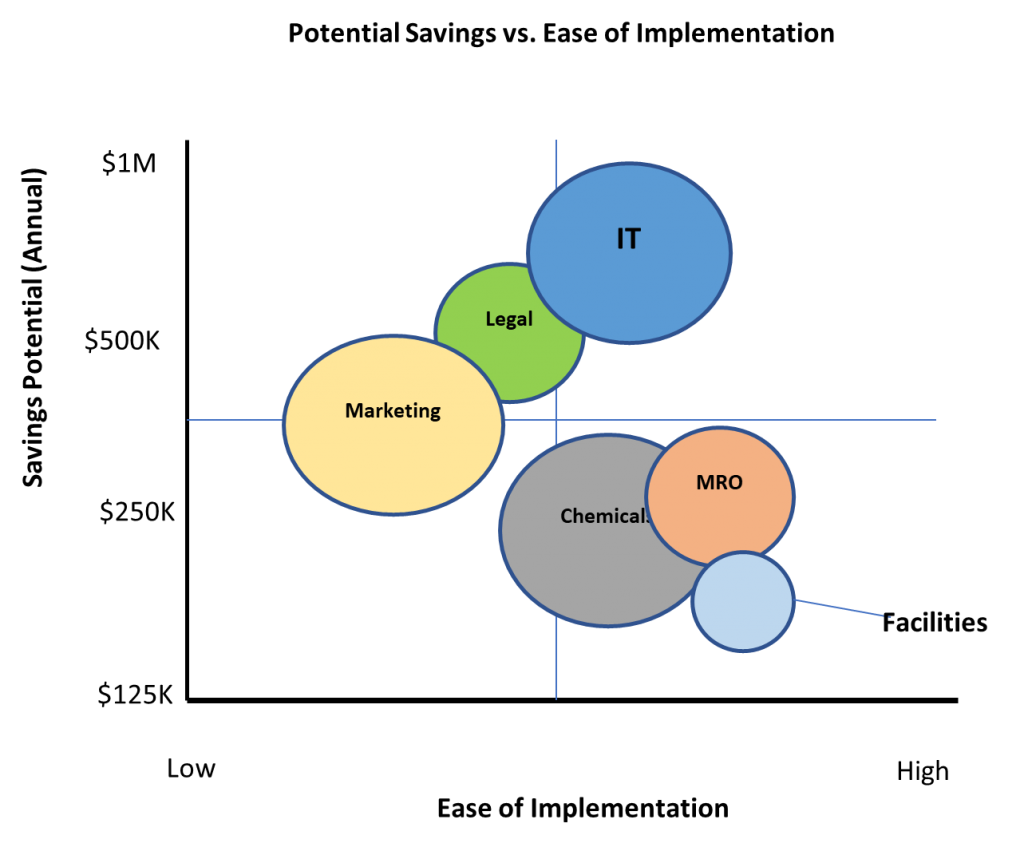

3. Make sourcing a strategic focus and a competitive advantage

Immediately review your category strategies. Are they working? Were they ready for the crisis? Engage in a new and more collaborative way with suppliers. Invest in the right tools, techniques and training to empower procurement teams to be value drivers. You don’t necessarily need a new system or a new org structure – just make sure you’ve positioned your people to make best use of what they have. Be ready to be agile and responsive

4. Continually focus on operational improvement in manufacturing and operations

Better run operations are inherently more efficient and more resilient. By taking an honest look at your operations, you can determine:

a. Are the right KPI’s in place?

b. Do we have a robust performance management system?

c. Do we have standardized policies and processes?

Operational Excellence enables organizations to recognize problems sooner, respond to changing conditions more smoothly, and adapt more effectively.

Tom Donatelli Joins OnDemand To Enhance Our Client Service Capabilities And Broaden Our Market Reach