Structured Rapid Sourcing Delivered Significant Savings To Mattress ManufacturerStructured Rapid Sourcing Delivered Significant Savings To Mattress Manufacturer

Today’s rapidly changing economy has created immense challenges for manufacturers as supply markets are in flux. Materials markets as sources of supply are contracting, slowing production or disappearing entirely. The current circumstances dictate that competitive manufacturers embrace a structured rapid sourcing approach to ensure that their products remain competitive in the current deflationary environment.

There are a number of success factors associated with Structured Rapid Sourcing which include:

- It is imperative to create a total cost model for the product to be supplied, including logistics and financing costs. Creation of a complete and transparent cost model gives the suppliers the confidence necessary to quote competitively.

- It is imperative to understand the supplier’s cost structure for the products to be supplied. Raw materials can represent anywhere from 10-70% of the ultimate sales price. Understanding the supplier’s cost structure is integral to the creation of a valid total cost model.

- Raw material markets have highly variable degrees of transparency, ranging from highly transparent markets for publicly traded metals like copper to somewhat murky markets for less common metals like tungsten or certain plastics or electronic components. When less transparent supplier commodity markets are involved, it is beneficial to go to the market on a more frequent basis.

- The buyer must have the ability to qualify multiple sources and to maintain those surveillances. Normally, qualifications should be established in advance of the negotiation to help manage risk and ensure that supply changes can be effected quickly, which increases the competitiveness of the market. In the current environment, it is as important to manage risk as to achieve cost savings.

MATTRESS MANUFACTURER CASE STUDY

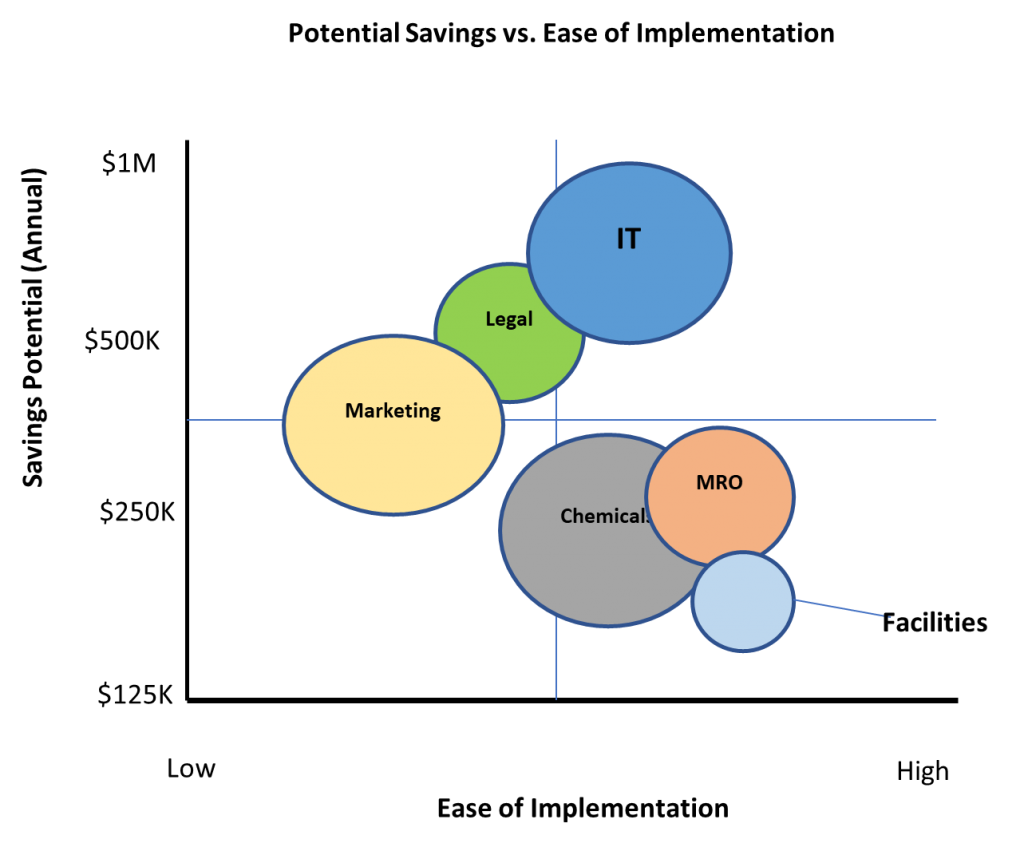

We recently completed a sourcing engagement for a PE-owned major manufacturer of mattresses under the leadership of OnDemand Partner Brian DelBarba. The sourcing organization had been stagnant for some time and incumbent suppliers were well-entrenched, especially the foam supplier. The markets for the main chemical components (TDI and Polyol) had been trending downward for some time and the adjustments offered by the main incumbent failed to reflect the market conditions. The existing sourcing team predicted a 1-2% cost savings opportunity with foam.

A total cost RFQ was created for the 20+ line items and 10+ delivery locations. Full cost breakdowns were requested as well allowing the buyer to compete their backhaul logistics as part of the award scenario. Instead of a single unit price, suppliers were encouraged to quote varying rates from their different production facilities. As a result true market pricing was achieved. Sourcing events were held quarterly and prices dropped precipitously over the course of two quarters as the supply base adjusted to the new process.

After the second event, foam costs on a delivered total cost basis were 28% below the initial prices. Profit margin for the company improved by over 5% as the result of this one category (similar results were achieved in other categories as well – in total, delivered $38 million in savings on $250 million addressable spend).

“One of the keys to the substantial savings Brian delivered that often goes overlooked is specifying exactly what we needed to buy. It is my belief that nearly every company either over- or under-specifies. Before sending anything out for quote Brian optimized our internal specifications, sent out RFIs to suppliers to see what they were capable of, and prepared the RFQs to optimize our profitability. Many companies will claim savings on a RFQ, but often buy more than they need (over spec) leading to a higher piece price or less than they need (under spec) leading to manufacturing issues. Brian brought a scientific / engineering approach leading to excellent savings.“

Chief Operating Officer

Meet Brian DelBarba – OnDemand Network Member Since 2005

Following stints as a nuclear submarine officer and mechanical engineer, Brian transitioned to a career as a technical strategic sourcing and engineering consultant, serving clients in the aerospace, industrial, automotive, and energy industries. For over 20 years, Brian’s areas of particular interest include consulting related to cost engineering, low cost country sourcing, supplier qualification and management, and design for sourcing. Brian holds a degree in aerospace engineering from the US Naval Academy and is a former registered professional engineer (mechanical).

Tom Donatelli Joins OnDemand To Enhance Our Client Service Capabilities And Broaden Our Market Reach